The TLC Process

Designed to Protect the Environment

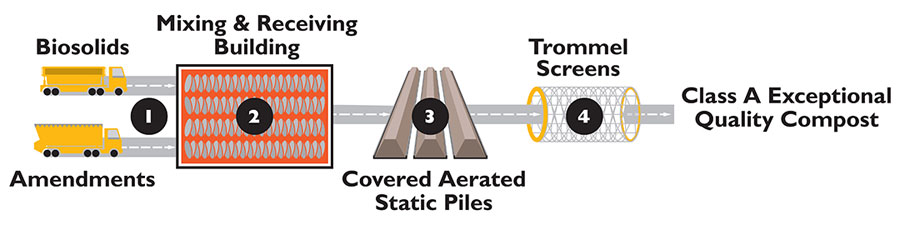

CLASS A EXCEPTIONAL QUALITY COMPOST IN FOUR STEPS:

-

Hauling: Natural gas fueled trucks arrive at the facility with biosolids and agricultural and green waste, called “amendments,” which add the carbon that is necessary to complete the composting process. TLC will receive six to seven biosolids trucks and one to two amendment trucks per day.

-

Mixing: As biosolids are delivered to the facility, biosolids trucks enter the Mixing and Receiving Building where the biosolids are unloaded indoors. Amendments are delivered and temporarily stored outdoors. The biosolids and amendments are combined using stationary mixers located inside the Mixing and Receiving Building or in a specialized mixer truck.

-

Composting: The blended material is delivered to the composting area where it is laid out in piles, covered with a breathable fabric or a biofilter layer, and broken down by the activity of tiny microbes. The composting area is equipped with an oxygen controlled, positively aerated system and an oxygen and temperature monitoring device. This system creates ideal composting conditions within the pile, while efficiently trapping odors and other emissions such as dust, ammonia, and volatile organic chemicals.

-

Screening: After the composting process is completed, the composted material is screened to produce a consistent product. Material too large to pass through the screen is returned to the composting process.